The new member of the Hitachi Hx family…

Hitachi HX Series PAC (Process Automation Controller) is the next generation industrial controller. With its “Stand Alone” structure, Hx PAC controller offers perfect control for all kinds of industrial areas from machine automation to system automation. Thanks to its IOT capabilities, it is ready for the next generation requirements in automation.

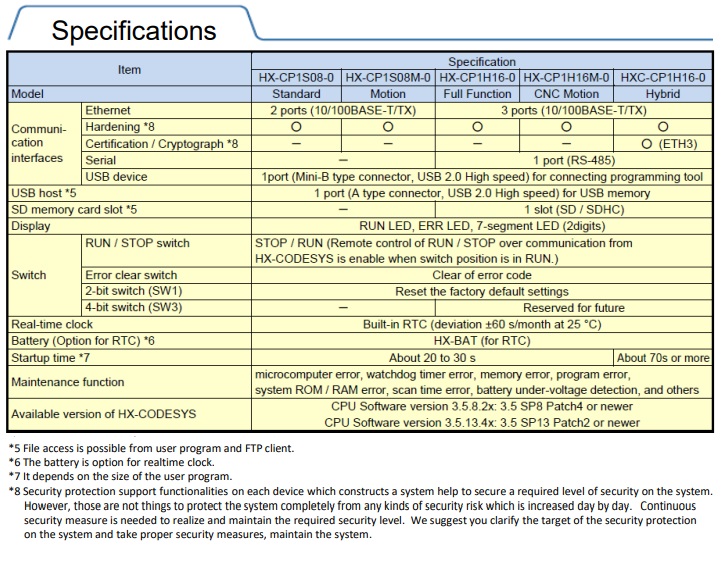

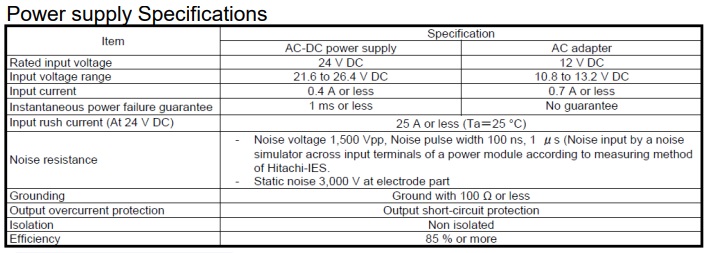

With its stand-alone structure, it does not need a base connection chassis and a special additional power supply. It is especially important for locations that do not need I/O next to the CPU. In a simple way, it provides space advantage in the panel by mounting on the rail and taking energy from the main power supply in the panel. With the advantages of Ethernet, EtherCAT communication in locations with scattered I/O structure, optional RS485 communication (depending on the model) does not require cable-wiring to collect all I/O signals in a single panel. With its 1ns processing speed, it offers excellent performance, especially in applications where motion control is required. It is ready for internal network communication such as OPC UA, IEC61131-3, Ethernet TCP/IP (up to 3 in a single CPU), EtherCAT, which may be required for automatic machines and production facilities. There are different models specially designed for different working structures with motion control, motion control, CNC systems, hybrid model options. There are also model options with SD card (Max. 32 GB) input support, especially for storing data logging records. While in PLC Run mode, logic can be written, loaded and pulled from 4 different points at the same time over the ethernet network.

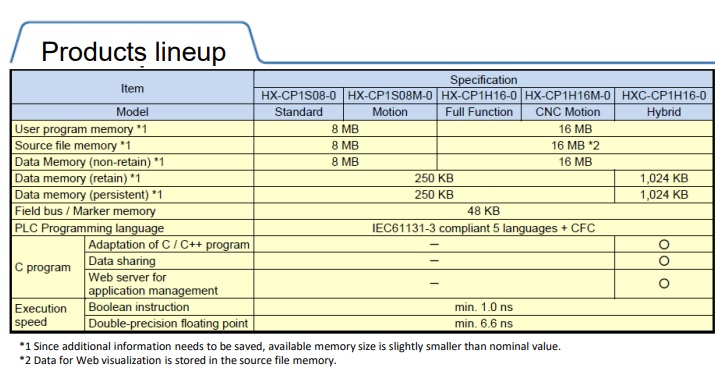

The option table according to model types and memory capacities is shown below.

There are different models with CPU memory capacity of 8MB and 16MB. In order to facilitate the programming of complex and large processes, IO tags and comments can be stored in the CPU, and which I/O is assigned to which task in the program flow can be easily followed. In such systems, it is usually necessary to work on the I/Os without cutting the power of the PLC. It is possible to disassemble and install the I/Os under energy of the modular HX PAC controller.

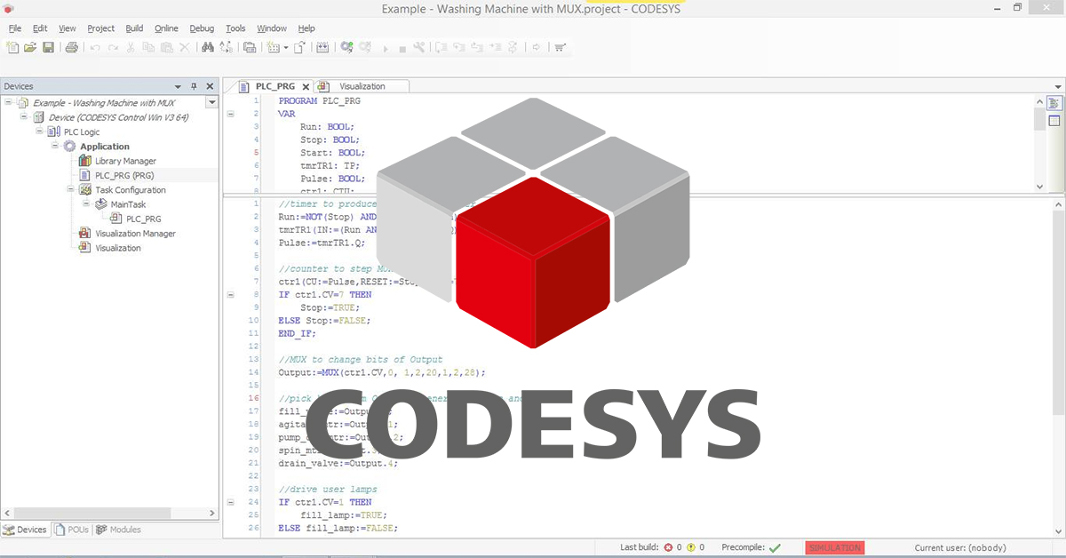

It can be programmed with Codesys as a user interface. In this way, all programming languages (LD, FBD, SFC, IL, ST and CFC) defined in IEC 61131-3 standards are used for PLC programming. Thus, the written program can be used independently of the brand.

The reason for choosing the PAC controller is production, cost and quality optimization. Now, businesses can revise and improve their systems by making IoT-based PLC applications within their own structure. It is necessary to support businesses with quality products and training in this regard. It is an important detail that the trainings and products given are directed to the systems applied in the field.

Hitachi HX series PAC controller can be used in various industries such as process and system automation, motion control, CNC (G Code) systems, energy automation, Iron and Steel industry. You can follow advanced detailed information and documents on our website www.cedetas.com.tr.

![]()