Electric motors are used at almost every point of factory and industrial sites. It is necessary to make sure that these engines are working in suitable working conditions in order not to interrupt the production of the enterprises. The mechanical and electrical stresses that occur on the motor over time reduce the life of the motor. In order to reduce these effects, it is necessary to start with frequency converters (drivers) instead of primitive starting methods. Frequency converters are microprocessor controlled electronic products. This advantage brings advanced protection parameters for both the motor and the driver and prevents possible damage to the motor in operation. It would be advantageous to prevent possible malfunctions before they grow, and the maintenance team within the enterprise to carry out maintenance in a more planned and less costly manner. The aim here is to ensure that the process is not disrupted and the life of the engine is extended.

Hitachi frequency converters make your work easier with advanced protection parameters. electric motors; They are exposed to the effects of over-current, over-temperature and over-voltage, and are subject to undesirable effects. These three values should be monitored in order to extend the life of the engine.

In these three cases, both the driver and the motor must be protected. Many similar protection functions can be monitored using frequency converters. All parameters in the frequency converter can be transferred to a controller or SCADA environment with a communication infrastructure (RS485 Modbus RTU, Profibus, Profinet, Ethernet..etc).

If we want to list the issues to be considered in articles;

- It should be selected according to the application type.

(For example: Fan, Pump, Mixer…etc.) - The operating temperature should be selected so that the drive can provide power without loss.

- Loading rate according to application type

(For example, 120% load in 60 seconds or 150% load in 60 seconds) - Is a special communication structure desired?

(For example Profibus DP, EtherCAT, Ethernet, Profinet..etc.) - IP protection class

(In some special applications, high IP protection may be required.)

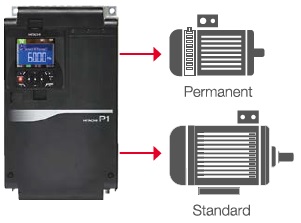

Frequency converter selection can be made according to the application and the nominal current value of the motor. In today’s technology, not only asynchronous motor type but also high efficiency PM motor types are used as standard. The frequency converter should be able to start these motor types as needed. Hitachi SJ-P1, SJ-S1, WJ200, WL200 and NES1 series provide solutions for you in choosing the right product according to your needs.

You can find detailed information about Hitachi frequency converter family and other products at www.cedetas.com.tr website.

![]()