PROJECT DESCRIPTION :

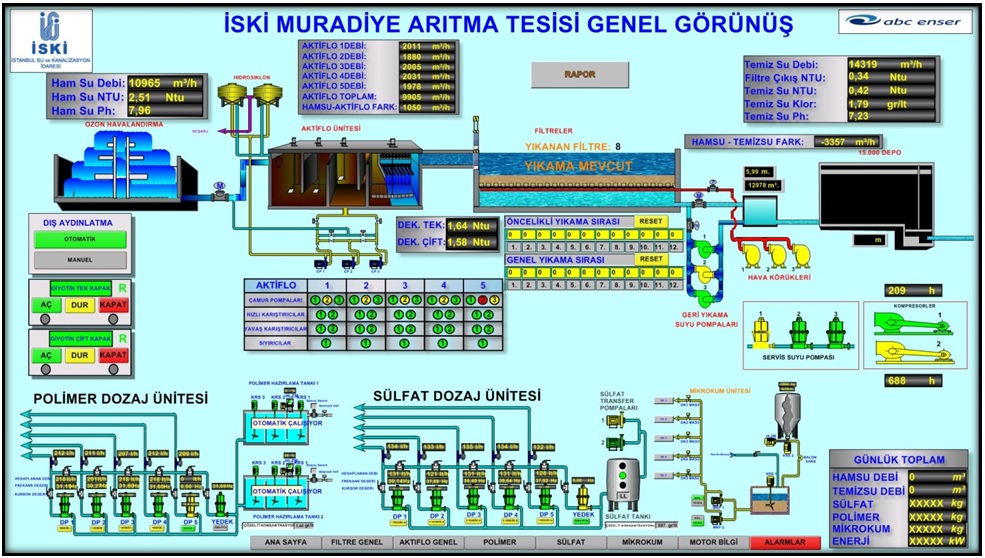

The project includes the revision of the automation system of the İSKİ Ömerli Drinking Water Treatment Branch, Muradiye Treatment Plant İstanbul / Turkey. ISKI Muradiye Treatment Plant automation revision is to modernize the existing system completely and to make the complete system suitable for automation.

In project scope;

- SCADA, SQL Server, 1 Master, 12 Filter, 2 MCC and 2 Polymer panels have been created. This system can be operated manually, semi-automatic and fully automatic. Monitoring and control can also be performed via SCADA and operator panels.

- Master PLC forms the main control point. All PLCs in the system communicate with SCADA via Master PLC. Single mode fiber optic lines are used to communicate with remote PLCs.

- 17 proportional valves, 54 pneumatic valves, 36 level transmitter, 19 flowmeters, 17 turnover guards, 4 turbidity, temperature and chlorine meters were used in the facility.

- In the section of Aktiflo units, a total of 20, fast mixer and slow mixer motors are operated by softstarter. 5 pieces of sludge scrapers are driven by frequency converters.

- In order to give way to 3 existing water pumps at the main feed input, 90KW / 170 A softstar, 55KW / 110 A softstarter for 3 air bellows, 2.2 KW for 12 chemical dosing pumps 15 KW softstarter is used to give way to frequency converters and 15 slurry pumps.