What is OPC (Open Platform Communications)?

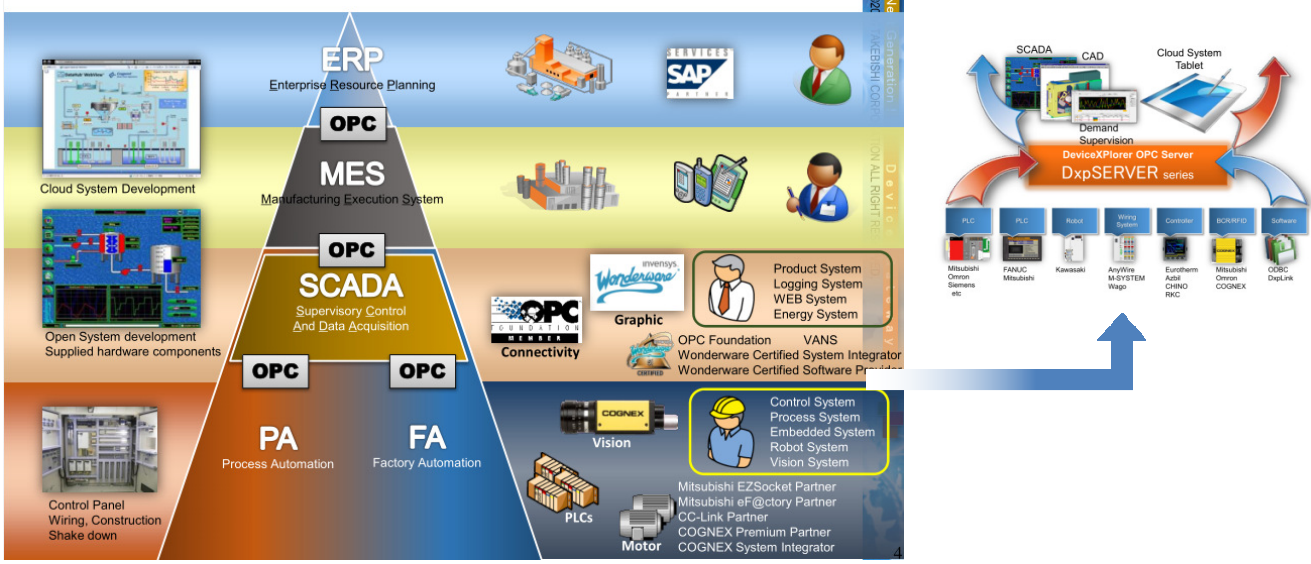

It is a standard platform created for data transfer and communication in industrial applications. OPC is a standard software-to-software communication interface.

- It allows devices of different brands and models to communicate with each other.

- There are many software packages around the world that support OPC.

- It reduces the waste of time by minimizing the need to write special software.

- Data access and control is provided by connecting to OPC servers in the control devices from OPC compatible clients.

OPC Sunucusu (OPC Server)

- Located on control equipment. Monitoring sensors enables data to be collected and presented.

OPC İstemcisi (OPC Client)

- Reads, writes, controls and monitors data on OPC servers.

- Required for systems working with more than one provider.

- Different brands and models of equipment are connected to each other with a standard communication method.

- DxpServer, CC-Link IE etc. protocols are supported.

DeviceXPlorer OPC Server (Takebishi)

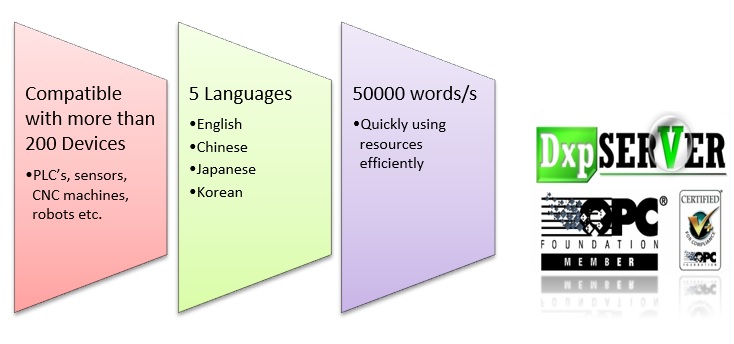

Takebishi has been a member of the OPC Foundation for many years and has been a pioneer in the development of standards.

- Compatible with more than 200 devices. PLCs, robots, barcode readers etc.

- All device drivers come with Enterprise edition.

- Compatible with up-to-date software interfaces.

- The software development team is located in Japan.

- Takebishi has strong business relationships with Mitsubishi and other Japanese manufacturers.

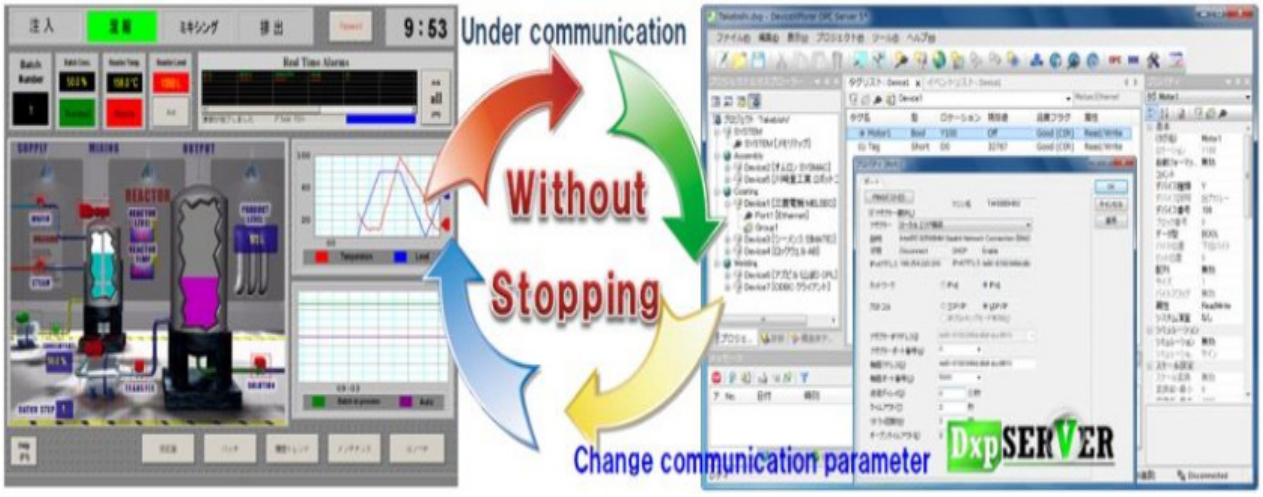

Hot-Swap Feature

Uninterrupted systems can be easily configured with DxpSERVER.

All parameters can be dynamically updated without disconnecting the controller.

Script Feature

Expansion and flexibility with Lua scripting support

Custom code can be placed inside the program loop or event-based

OPC functions, data logging, debugging etc.

Creating Data Structures

By creating the desired data structures, even the most complex systems can be constructed as object-based.

User Authorization

Misuse is prevented by making authorization settings for all features of the server.

Data Bridging

Servers, controllers and stand-alone systems can be interconnected using bridging.

Data can be bridged as a group or as a tag.

Arithmetic operations etc. with data manipulation.

Simulation

System design can be done without PLC.

There are sin, ramp, random, shared memory simulation options.

Client Software

Tested with many client software

Selected by ICONICS USA to be integrated into Genesis64.

SCADA; InTouch/Historian (Wonderware), GENESIS (ICONICS), Cimplicity/iFix (GE), RSView (Rockwell),WinCC (Siemens), Citect SCADA (Schneider Electric), JoyWatcher (JT Engineering), ASTMAC (Yokogawa), Monity (MCR), KingView (WellinTech).

3D CAD VIRTUAL SIM; DELMIA (Dassault Systemes), iCAD/VPS (Fujitsu), Vmech (Lattice Techonology), 3DCreate (CMS), SMASH (Sanmatsu).

OTHER; Harmonas/PREXION/DGPL (Azbil), LabVIEW (Natinal Instruments), Cogent DataHub (Cogent), DxpLOGGER (Takebishi).

OPC UA PUB/SUB

DxpServer complies with the OPC UA 1.04 specification.

For networks in mesh topology, it has a faster and latency-free communication method compared to traditional server/client configuration.

It publishes data under a certain title with its Publisher feature.

With the subscriber feature, it receives the broadcasts according to the desired title.

License and Support

The license is one time only.

Unlike products that use a subscription system or a plugin system, the costs do not increase over time.

The licensing process is easy and user-friendly.

The user manual is written in clear English.

![]()